Exosens’ advanced gamma and neutron detection technologies are critical in enhancing nuclear safety and supporting scientific research.

With deep expertise in the design and manufacturing of high-performance radiation detectors, Exosens provides essential solutions for monitoring and controlling nuclear reactors, fuel reprocessing plants, waste storage facilities, and research centers around the world.

Neutron detection as a technology

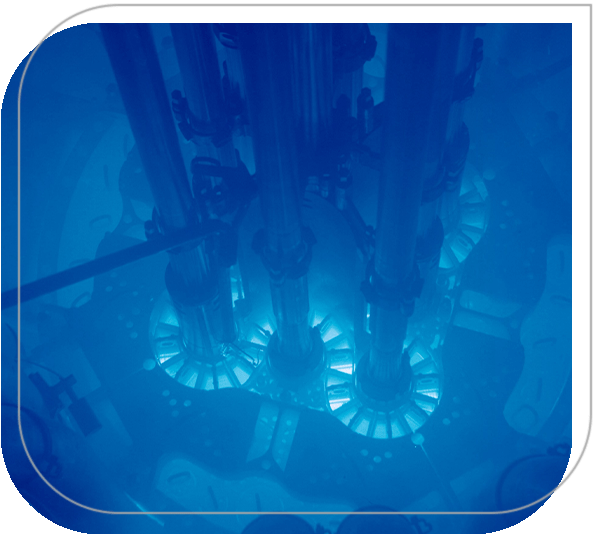

As a neutron has no charge, a neutron detector must incorporate a neutron-to-ionized particle converter. The incident neutrons are captured by the converter material which then produces (detectable) ionized particles by means of a nuclear reaction.

Exosens gas-filled detectors are specifically engineered to detect thermal neutrons (energy < 0.025 eV). To ensure high neutron capture efficiency at these low energies, we utilize materials with large capture cross-sections:

- Uranium-235 (580 barns at 20 °C) is used in our fission chambers,

- Boron-10 (3840 barns at 20 °C) is employed in our boron-lined proportional counters.

For applications involving higher-energy neutrons, Exosens also maintains the capability to use Uranium-238 as a detection medium.

Fission chambers are vital for neutron flux monitoring in nuclear reactors. They are used to detect thermal neutrons in high-flux environments, monitor fuel burn-up, and control reactor power levels across the source, intermediate, and power ranges.

Exosens gas-filled neutron detectors are designed to operate in three distinct modes:

- Pulse Mode: Detects and counts individual pulses, making it ideal for low-level neutron flux monitoring in the source range.

- Campbell (Fluctuation) Mode: Analyzes current fluctuations to suppress gamma noise, suitable for intermediate and power range applications.

- Current Mode: Measures the average current signal for precise monitoring in the power range.

Each fission chamber is filled with gas optimized for fast response and high-temperature operation, ensuring exceptional radiation resistance and long-term reliability in demanding nuclear environments.

Gamma detection as a technology

Gamma detectors operate by converting gamma radiation into measurable electrical signals. When gamma photons interact with the detector’s cathode material and filling gas, they generate high-energy electrons. These electrons ionize the gas, producing charge carriers that are collected by the electrodes and delivered as a direct current to the measurement electronics.

Primary electron production occurs through three key interaction mechanisms:

- Photoelectric Effect

- Compton Scattering

- Pair Production

The efficiency of each mechanism depends on several factors, including the gamma photon energy, the type and thickness of the cathode material, the composition of the filling gas, and the gas pressure. As a result, gamma detector sensitivity is highly dependent on both the energy of the incoming radiation and the specific detector design.

Due to the dominant role of the photoelectric effect at lower energies, gamma detectors typically achieve peak sensitivity around 80 keV. At higher gamma energies (above 500 keV), sensitivity can decrease significantly—often to just one-hundredth of the maximum—depending on the mechanical and material configuration of the detector.

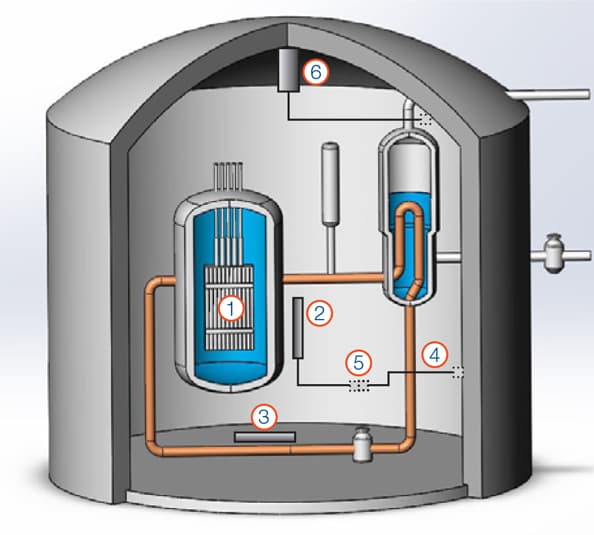

Examples of product applications in a nuclear power plant

1. In-core detectors (Neutron Flux Mapping – I&C)

- Fission chambers 235U

2. Ex-core detector (Neutron Flux Monitoring system – I&C)

- 10B proportional counter for source range

- Fission chambers 235U for intermediate and power ranges.

3. Boron concentration meter (Chemical Monitoring System – I&C)

- 10B proportional counter

4. MI Cables (Signal transmission system – I&C)

- Mineral insulated cable extension

- Feedthrough

5. Connectors for severe environment

- Signal transmission system – I&C

6. Gamma ion chamber detector (Radiation Monitoring System – I&C)

Decades of Experience and Global Presence

Exosens has been at the forefront of nuclear instrumentation since the early 1940s, building deep expertise through long-standing collaborations with the French nuclear industry and national research programs. Over the past decade, our reach has expanded worldwide, with trusted partnerships in countries including Sweden, Bulgaria, China, the Czech Republic, Slovakia, Switzerland, Ukraine, and the United States.

Advanced Nuclear Instrumentation Technology

The Nuclear Instrumentation division at Exosens is dedicated to designing, developing, and deploying precision instruments that detect, measure, and analyze radiation across a wide range of nuclear and radiation-related applications.

Our technologies are built to meet the most demanding operational and regulatory environments. We maintain rigorous quality and compliance standards, operating in accordance with:

- ISO 19443

- NQA-1

- HAF-604

- CSA Z299.2, N299.2

- QN-100 Generic Rev. B

- KTA1401 (2017-11)

- IAEA 50-C-Q; GSR Pt2; GS-R-3

- 10CFR50 Appendix B / Part 21

- NSQ-100

Tailored Solutions for the Nuclear Industry

Exosens designs and manufactures advanced neutron and gamma detectors specifically for the demanding needs of the nuclear industry. Our technologies play a vital role in nuclear power plants, fuel reprocessing facilities, radioactive waste monitoring, and nuclear research environments.

Engineered for extreme conditions, Exosens detectors ensure reliable performance under high radiation levels, elevated temperatures, increased external pressures, and in critical scenarios such as Loss of Coolant Accidents (LOCA) and post-LOCA conditions.

We are also actively supporting the evolving needs of Small Modular Reactors (SMRs) and Advanced Reactors, working closely with developers to deliver tailored instrumentation solutions that help advance a more sustainable energy future.

Versatile Detector Technologies

Exosens offers a broad portfolio of radiation detectors compatible with a wide range of reactor types and operating environments. Our expertise extends across pressurized water reactors (PWRs), boiling water reactors (BWRs), heavy water reactors (HWRs), and other reactor designs.

Our longstanding partnerships with leading industry players—including Électricité de France (EDF), Framatome, CEA, TechnicAtome, and ORANO—reflect our commitment to innovation, quality, and reliability in nuclear detection technology.

Global Reach and Impact

Exosens I&Cs are trusted worldwide, with installations in over 30 countries, including the United States, the United Kingdom, France, China, India, and across Western Europe. Designed for reliability and precision, they support critical safety applications in nuclear facilities globally. Power reactor installation types include Boiling Water Reactors (BWR), Pressurized Water Reactors (PWR), and Water-Water Energetic Reactors (VVER), as well as advanced and research reactors globally.

Other installation references include fuel reprocessing plants, Accelerated Driven Systems (ADS), Fast Breeder Reactors (FBR), and TOKAMAK.

Driving Innovation and Research

Exosens’ advanced gamma and neutron detection technologies are essential to the progress of reactor instrumentation and control—ensuring both operational safety and scientific discovery. Our detectors are trusted components in critical systems across nuclear power plants, research facilities, and experimental platforms worldwide.

With a firm commitment to quality, technological excellence, and global collaboration, Exosens continues to help shape the future of nuclear technology—driving advancements that support a safer, more efficient, and sustainable energy landscape.

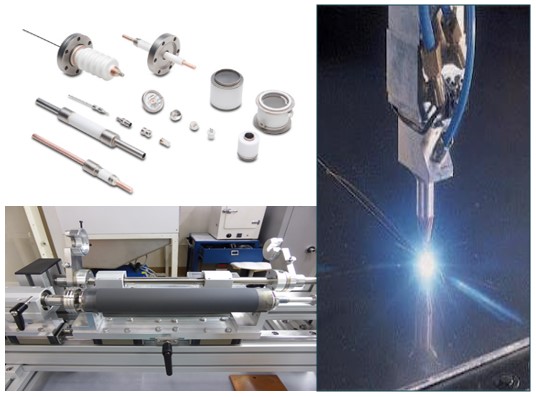

Our Know-How

With fully integrated in-house capabilities, including precision machining, inspection, engineering, and radiological testing, Exosens maintains full control over its production processes to ensure unmatched reliability and performance. Our multidisciplinary team of scientists and engineers—experts in physics, materials science, and electronics—work closely with customers to deliver tailored solutions that meet the most rigorous industry standards.

- Ceramic to metal bonding

- Boron layer deposition by CVD

- HEU layer deposition

- Argon Arc welding

- Laser welding

- Gas filling

- Neutron measurement testing

- Nuclear QA for QRA components

Products 18

See all exosens products

What's new in Gamma and Neutron technology?

See all

Oct 09th 2025

High-Temperature Detectors for Next Generation Reactors

Proven reliability up to 800°C and beyond for SMR and AMR applications. Built on the combined legacy of Photonis and Centronic—80+ years of neutron detection excellence.

Paris.

FROM Nov 04th 2025 TO Nov 06th 2025

WNE 2025

Join Exosens at the World Nuclear Exhibition (WNE) 2025, the leading global event for the civil nuclear industry, taking place at Parc des Expositions Villepinte in Paris, France.

Jul 10th 2025

Spotlight on Geiger-Müller excellence

Exosens: Fundamental Detector Technologies Powering Trusted Radiation Detection